As Built Data (formerly Survey 2 CAD) employ experienced in-house 3D Laser Scanning Survey teams to rapidly capture field scan data, using the latest equipment, from small to very large projects, over the whole process plant spectrum.

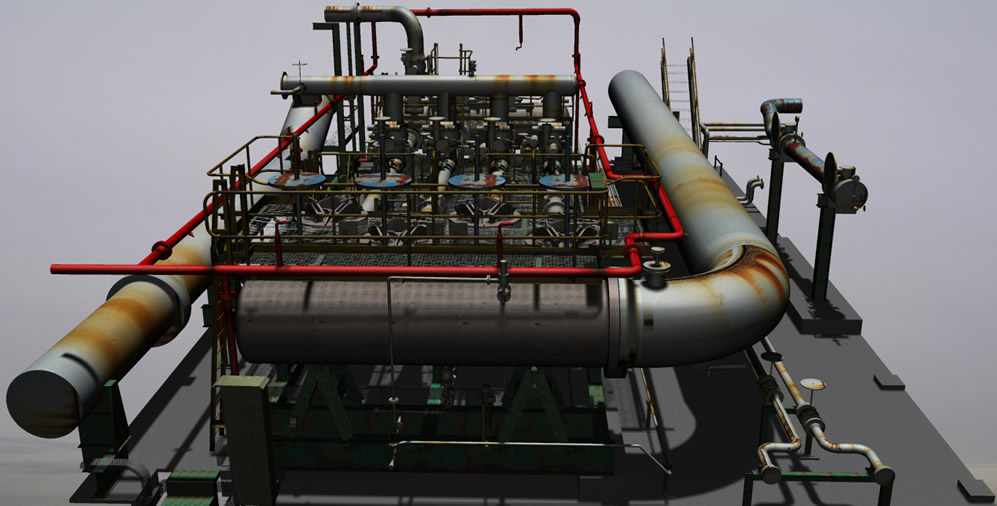

3D Scan data can then be delivered to the client as Point Cloud Data or converted to a 3D As built model for use with our client's CAD package.

Field Work Procedure

Laser Scans are captured from numerous locations, total numbers ranging from several to several thousand, dependant on the size of the facility. The scans are then registered using X,Y,Z positions visible within each scan and previously recorded using a Total Station Theodolite.

This improves overall survey control and the accuracy of the scan data. Individual scans may then be used or combined to form blocks of scan data for further processing into an As built CAD model.

Applications

Which projects would benefit from using 3D Laser Scanning?

Almost any project which requires accurate as built information can benefit from using our 3D solutions as a way to keep costs down and make cost-time savings.

Which Industries are currently using 3D Laser Scanning solutions?

Currently, As Built Data are providing 3D Laser Scanning measurement solutions to clients working in the following sectors:

- Oil & Gas

- Utilities Industry

- Process Plant Industry

- Chemical Industry

- Marine

- Nuclear

- Automotive

- Manufacturing

Deliverables

How can my company use the information provided?

As Built Data offer a range of deliverable options to meet your as built data requirements. 3D Point Cloud Data can be delivered for use with packages such as LFM, RealityLinx and Cyclone.

Alternatively, you can have your 3D Scan Data converted into a 3D As built CAD model, suitable for use with all major 3D Design packages including P.D.M.S., AutoCAD, Microstation, P.D.S. and RealityLinx.

Key Benefits

- Rapid data capture of large volumes with increased accuracy

- Shorter project times with rapid turnaround of information

- Unobtrusive data capture methods

- Enables accurate off-site fabrication and first-time fit installations

- Improved safety due to less time pent working in hazardous environments

- Fewer Surveyors, taking up expensive time and space on Offshore Platforms

- Eliminates costly 'return visits' to site

- Keep your project on schedule with advanced project planning using accurate and rapidly provided data.